Crowd Funding page is here

(Funding period has ended)

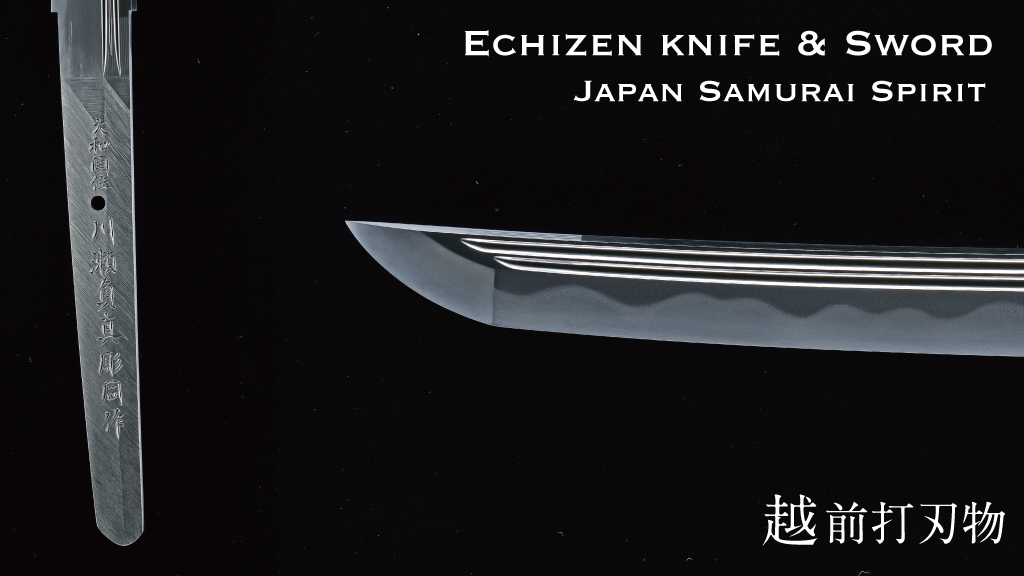

This is a collaborative crowdfunding campaign between a young swordsmith, Yujiro Kawase, who wants to continue the Japanese sword making technique and Ryusen Hamono, a renowned chef’s knife maker that bases the manufacturing of its daily-used knives on traditional sword-forging.

The Story of the Echizen Kitchen Knife and its Sword-forging origin

The Echizen area has a long legacy of manufacturing kitchen knives over 700 years old.

Even now, the region still manufactures these chef’s blades based on the hand forging and striking techniques passed down from the Muromachi era.

These blades also have the Japanese government’s seal of traditional craft.

Although the kitchen knife is a well preserved traditional technique, the original sword technique is no longer being practiced, that is until two years ago.

Sword making is a process that takes specially trained skills, years of apprenticeship, and immense patience for the long duration of time a piece takes.

After training with Nara swordsmith master, Sadatoshi Gassan, Yujiro Kawase returned to Echizen and opened a sword-forging studio of his own under a swordsmith name, Sadazane Kawase, to continue this tradition of Japanese sword making.

In this campaign, your support will go towards helping him pass down this authentic Japanese technique to future generations.

We interviewed Kawase and asked him about the sword making process.

K: Making a Japanese sword takes more than one year, and depending on the situations, it can take up to two years.

They’re made beginning with carefully selecting iron ores and forging from scratch, and steel is selected based on the expert knowledge.

Rather than everyday use like the kitchen knife, the Japanese sword could be regarded as an art piece that has immeasurable value.

Kawase who grew up with many relatives who are artisans, particularly gravitated toward swords and wanted to continue this traditional craft.

K: The Japanese sword has a history that has spanned over a thousand years and still continues today. I think there is a reason this art still exists, and that history is something I would like to learn more about.

To hone a sword takes numerous folding of soft and hard steel for the beautiful pattern to surface on the blade.

To start, the steel ore is heated in the fire to to 1200 to 1300 celcius then hit repeatedly by a hammer to get rid of impurities.

The cycle is repeated countless of times. Hamon, or blade pattern, with a wave down the center is made from countless splashing of boiling earth, this repeated boiling is a method that reflects the tough spirit of the Kamakura samurais.

To thank you for your support we have a 小刀, or small blade as a part of the rewards that you can order.

We also have tours of the studio where you can come see the traditional technique in practice at Kawase’s studio.

About Ryusen Hamono

As the Japanese sword is a meaningful root to the Echizen kitchen knife technology, Kouji Masatani, director of Ryusen Hamono wishes the young swordsmith can be successful in continuing the sword craft, believing it will bring a positive impact to the whole area.

The Echizen Uchihamono (forged blade technique used for kitchen knives) is a diligently preserved hand-crafted technique that traces its roots to 1337 in the Muromachi era.

It is said that its origin is by a Kyoto swordsmith named Chiyozuru Kuniyasu who went to live in Fuchu City (Echizen City, Fukui, today) in search of a good area for swords production when he began making sickles for farmers.

The technique evolved into knife tools for the daily lives of farmers and the original Hizukuri-forging and hand-finishing techniques that were used in ancient times is continued today.

Uchihamono craftsmen in Echizen came to specialize in the creation of these high-quality traditional Japanese blades.

Ryusen Hamono is one of these Uchihamono studios continuing this sword-traced-craft.

They form their knives to fit how people use them in the kitchen in their daily lives, making pieces that are easy to use on the hand.

They also pay particular attention to its ergonomics, function, shape, and is on a constant pursuit of evolving the technique to create beautiful pieces people want to posses for a long time.

As an already renowned kitchen knife maker whose products are used by famous chefs, you can be assured of their quality and value of Ryusen’s knives and products.

Rewards

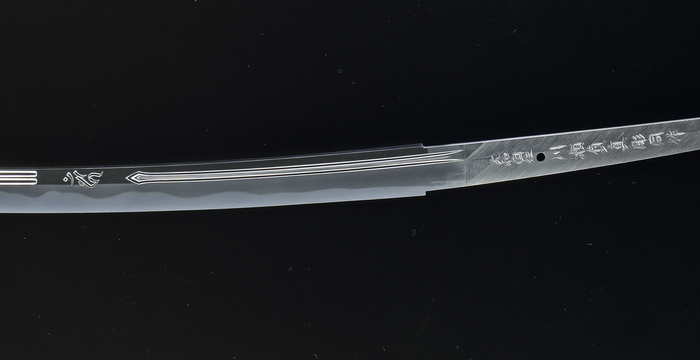

Kogatana (By Swordsmith Sadazane Kawase)

(Includes a white sheath & silver habaki)

The kogatana is a beautiful piece for display of simplistic beauty that exhibits strength and the Samurai spirit.

It can be used practically as a cutter for fabric, paper, and ropes, and as a wood sharpener.

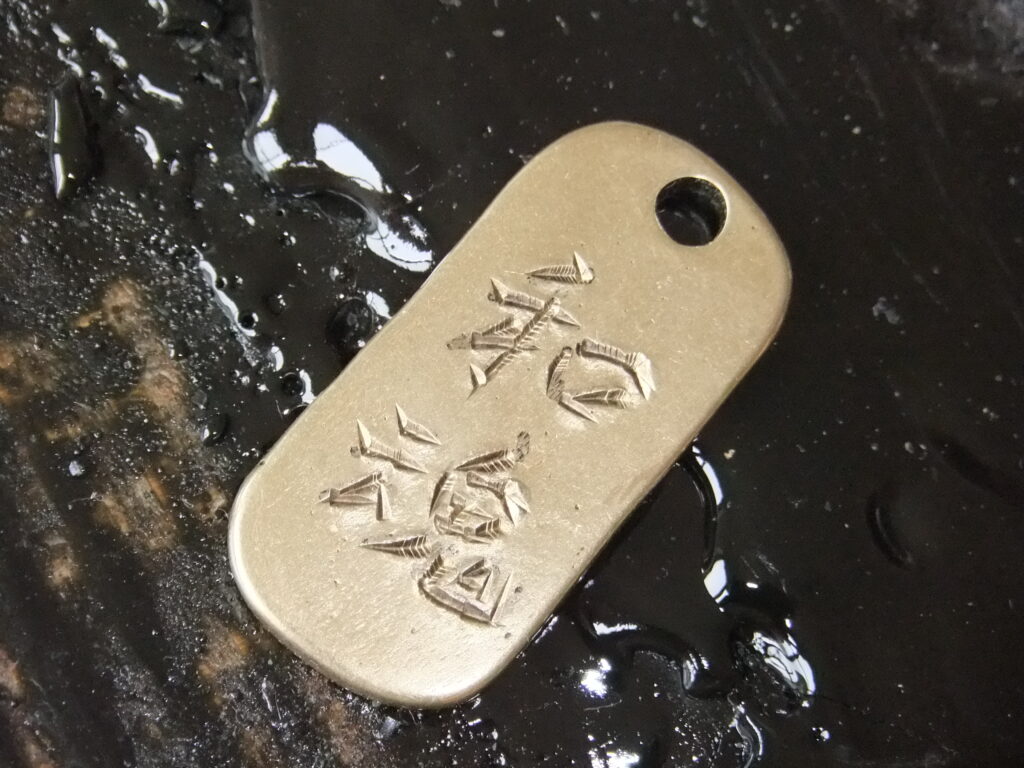

”Meikiri” Inscription key rings (By Swordsmith Sadazane Kawase)

It is a special strap that engraved “inscription cut” which craftsman makes Japanese sword. Craftsman carefully carved stroke one by one on a metal plate.

The inscription cuts represents the high technology of Japanese sword craftsman.

Let’s carry on the essence of the Japanese sword and enjoy it everyday.

Tour of the Studio in Echizen (By Swordsmith Sadazane Kawase)

Tour of the Studio in Echizen, converse with Kawase san about samurai swords and Order a sword in person

With the tour of Kawase’s sword forging studio in Echizen, you can see the beautiful place that is rich in clean water, earth, and steel ore that is ideal for forging knives and swords.

You can converse with Kawase san about samurai swords and place an order in person with customized engravings like your name in Kanji letters.

Ryusen Coaster

(Material: leather; side A – black with logo; side B – cognac)

With a limited quantity of 50, the coaster is unsold and is typically exclusive to visitors of the manufacturer.

For this special occasion, we will specially send it to you to thank you for your support!

Ryusen Keyholder

(Material: Stainless Steel)

The keyholder is made from the same steel used to make the kitchen knives.

Ryusen Sharpening Stone

(Material: VG10, SGII, ATS314 Stainless Steel)

This is an original sharpening stone made by Ryusen Hamaono and it is essentially a smaller version of what artisans use when they work on the knife finish.

Ryusen Urushi Fukaku Ryu 風格龍 Kitchen Knife

(Material: ATS314 Steel core with 63-layers of Damascus Stainless Steel, Canadian Curly Maple handle with Urushi lacquer; includes sheath and box)

From Ryusen Hamono, this is the recent collaborative model of the Fukaku Ryu knife in conjunction with lacquer craftsmen of Echizen.

Ryusen Rin 龍泉輪 Kitchen Knife

(Material: VG-2 stainless steel core clad with 70-layered Damascus stainless steel, Canadian Curly Maple handle; includes sheath and box)

The beautiful patterns on the blade is named Ryusen-Lin. It is a distinctive technique passed down by Ryusen Hamono craftsmen through the ages.

Multi-layers of soft and hard steel are forged and the surface is polished completely. Having this pattern all the way to the edge of the blade allows for extreme sharpness.

Crowd Funding page is here

(Funding period has ended)